LASER CLEANING

Laser Cleaning and coating removal is a process taking advantage of the latest in laser technology.

how it works

By laser irradiation, debris and impurities are being removed of various surfaces including metal, plastics, composites and even glass.

In the cleaning process, the coat (rust, paint, oil, …) absorbs the laser beam, resulting into vaporization of the coating with very small impact to the underlying material.

This solution is the most environmentally friendly application when comparing to conventional cleaning processes, currently used in the industry.

APPLICATIONS

- Welding and Coating Pre treatment

- Contamination Removal

- Art Restoration

- Surface Preparation

- Fascade and Fascia Cleaning

- Mold cleaning

- Rust Removal

- Paint Removal

- Aerospace Parts Cleaning

SEE VIDEOS

CLEAN BEARING

CLEAN PROFILE

CLEAN COAR REMOVAL

CLEAN SURFACE PREP

what we do

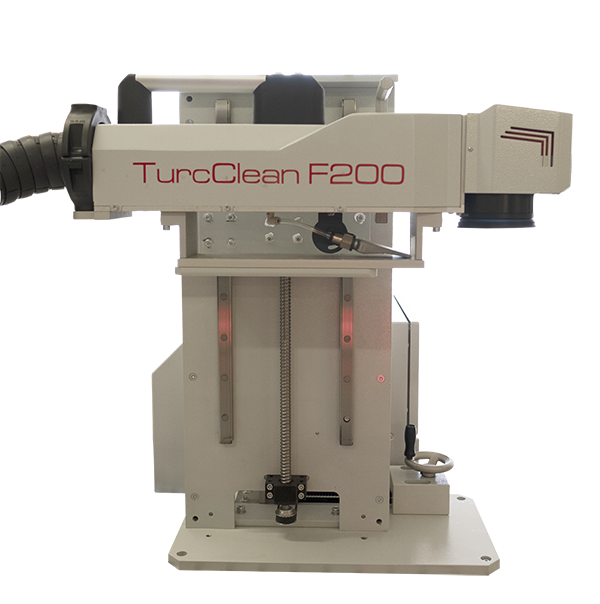

Triton Laser Solutions is utilizing quality European Equipment only to guarantee highest quality of our services paired with European Safety Certifications to ensure highest Safety Standards.

Triton’s provided services are cost effective and time efficient, making them available from small to big, throughout industries.

We are a mobile based, easy to deal with service, doing the required work on site for a fast turn around and guaranteed customer satisfaction.

ADVANTAGES

- Non–Contact Process

- Environment Friendly

- Automation Possibilities

- Cost effective

- No Consumables

- High Speed Process

- Minimal Thermal Effect

- High Precision Process

- Faster Application & Robust Results